Layout of steam power plant

Layout of steam power plant

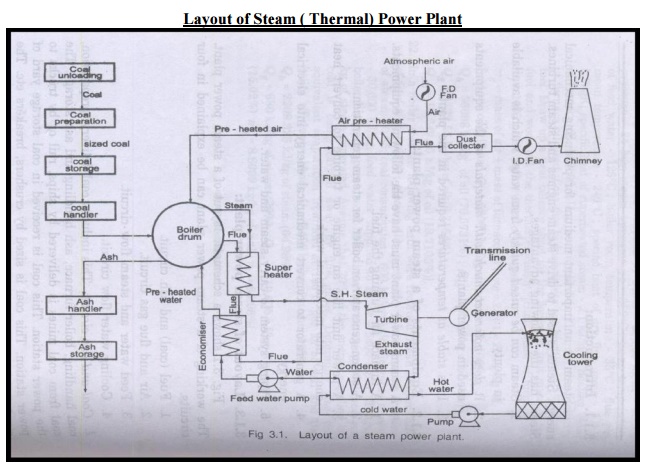

The layout of steam power plant has the following circuits:

1. Fuel (Coal) and ash circuit

2. Air and flue gas circuit

3. Feed water and steam flow circuit

4. Cooling water flow circuit.

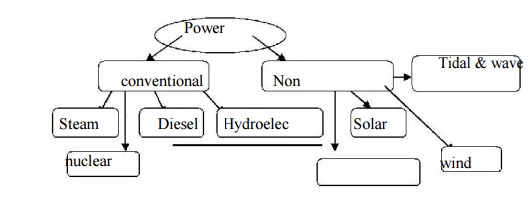

CLASSIFICATION OF POWER PLANTS

reasons:

- Steam can be raised quickly from water

- It does not react much with materials.

- It is stable at temperatures required in the plant

LAYOUT OF STEAM POWER PLANT:

The layout of steam power plant has the following circuits:

- Fuel (Coal) and ash circuit

- Air and flue gas circuit

- Feed water and steam flow circuit

- Cooling water flow circuit.

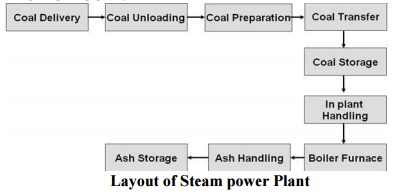

1 COAL AND ASH CIRCUIT:

Layout of Steam power Plant

Coal and Ash Circuit:

- Coal from mines is delivered by ships, rails or trucks to the power station.

- Coal received at coal yard.

- Coal is sized by crushers, breakers etc.,

- The sized coal is stored in coal storage.

- From stock yard, the coal is transferred to the boiler furnace by means of conveyors, elevators etc.,

- The coal is burnt in the boiler and ash is formed.

- Ash coming out of the furnace will be too hot, dusty and accompanied by poisonous gases.

- The ash is transferred to the ash storage.

- Generally the ash will be quenched to reduce the temperature and the dust content.

2 AIR AND FLUE GAS CIRCUIT:

- Air is taken from the atmosphere by the action of FD fan.

- It is passed through an air pre heater

- The air is preheated by the flue gases in the pre heater.

- This preheated air is supplied to the furnace to aid the combustion of fuel.

- Due to the combustion of fuel the flue gases are formed.

- The flue gases from the furnace pass over the boiler tubes and super heater tubes.

- Then the flue gases pass through economiser to heat the feed water.

- After that it passes through a dust collector.

It is then exhausted to atmosphere through chimney

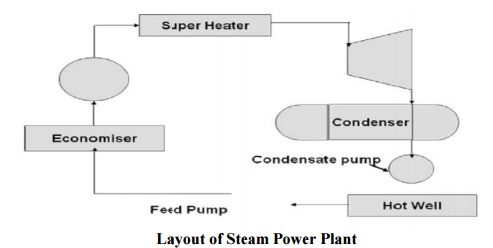

3 WATER AND STEAM CIRCUIT

Layout of Steam Power Plant

Water and Steam Circuit:

- The water is preheated by the flue gases in the economiser.

- This preheated water is then supplied to the boiler drum.

- Heat is transferred to the water by the burning of the coal.

- Due to this, water is con verted into the steam.

- The steam raised in boil er is passed through a super heater.

- It is superheated by the flue gases.

- The turbine drives generator to produce electric power.

- The expanded steam is t hen passed through the condenser.

- In the condenser, steam i s condensed into water there circulated.

4 COOLING WATER CIRCUIT:

- The exhaust steam from t he turbine is condensed in the condenser.

- In the condenser, the cold water is circulated to condense the steam into water.

- The steam is condensed b y losing its latent heat to the circulating the col d water.

- Hence the cold water get s heated.

- This hot water is then ta ken to a cooling tower.

- In cooling tower the water is sprayed in the form of droplets through nozzzles.

- The atmospheric air ente rs the cooling tower from the openings provided at the bottom of the tower.

- This cold water is again circulated through the pump, condenser and the cooling

- Some amount of water may be lost during circulation.

- Hence make up water is added to the pond by means of a pump

Layout of Steam ( Thermal) Power Plant

Energy Conversion Process:

Chemical Energy (Fuel/Coal) — >

Heat Energy(Boiler) — >

Mechanical Energy(Turbine) — >

Electrical Energy(Generator)

Advantages of Steam Power Plant (Thermal plant)

- Life of plant is more (25-30 years ) compared to Diesel plant (2-5 years)

- Repair and maintenance cost is low when compared to diesel plant. Initial cost is less compared to nuclear plant.

- Suitable for varying load conditions.

- No radioactive harmful wastes are produced

- Unskilled operators can operate the plant.

- The power generation does not depend on the water storage.

- There are no transmission losses, as they are located near load centres.

Disadvantages of thermal power plant:

- Less efficient than diesel plants.

- Starting up and bringing into service takes more time.

- Cooling water required is more.

- Space required is more.

- Storage required for the fuel is more.

- Ash handling is a big problem

- Not economical in areas which are remote from coal fields.

- Manpower required is more.

- For large units, the capital cost is more.

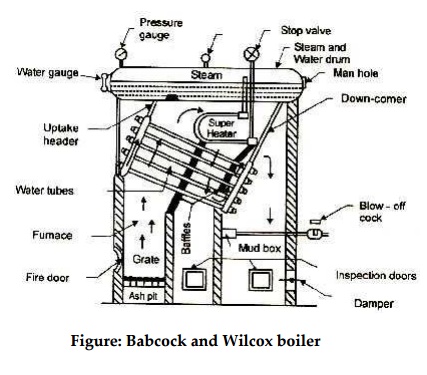

Water Tube Boilers: Babcock and Wilcox boiler

It is a water tube boiler used in steam power plants. In this, water is circulated inside the tubes, and hot gases flow over the tubes.

Water Tube Boilers: Babcock and Wilcox boiler

It is a water tube boiler used in steam power plants. In this, water is circulated inside the tubes and hot gases flow over the tubes.

Description:

The Babcock and Wilcox boiler consists of

- Steam and water drum (Boiler shell)

- Water tubes

- Uptake –header and down –comer

- Grate

- Furnace

- Baffles

- Superheater

- Mud box

- Inspection doors

- Damper

- Steam and Water drum (Boiler Shell)

One half of the drum which is horizontal is filled up with water and steam remains on the other half. It is about 8 metres in length and 2 metres in diameter.

- Water tubes

Water tubes are placed between the drum and the furnace in an inclined position (at an angle of 100 to 150) to promote water circulation. These tubes are connected to the uptake –header and the down –comer as shown.

- Uptake –Header and Down –comer (or Down take –Header)

The drum is connected at one end to the uptake –header by short tubes and at the other end to the down –comer by long tubes.

Figure: Babcock and Wilcox boiler

Grate:

Coal is fed to the grate through the fire door.

Furnace:

Furnace is kept below the uptake –header.

Baffles:

The fire –brick baffles, two in number, are provided to deflect the hot flue gases.

Superheater:

The boiler is fitted with a superheater tube which is placed just under the drum and above the water tubes.

Mud box:

Mud box is provided at the bottom end of the down –comer. The mud or sediments in the water are collected in the mud box and it is blown –off time by means of a blow –off cock.

Inspection doors:

Inspection doors are provided for cleaning and inspection of the boiler.

Working principle:

Coal is fed to grate through the fire door and is burnt.

Flow of flue gases:

The hot flue gases rise up ward and pass across the left –side portion of the water tubes. The baffles deflect the flue gases and hence the flue gases travel in a zig –zag manner (i.e., the hot gases are deflected by the baffles to move in the upward direction, then downward and again in the upward direction) over the water tubes and along the superheater. The flue gases finally escape to the atmosphere through the chimney.

A continuous circulation of water from the drum to the water tubes and water tubes to the drum is thus maintained. The circulation of water is maintained by convective currents and is known as ‚natural circulation‛.

Superheating:

Steam is taken from the steam space of the drum through a tube to the superheater. Steam is superheated in the superheater, as it receives additional heat.

A damper is fitted as shown regulate the flue gas outlet and hence the draught.

The boiler is fitted with necessary mountings. Pressure gauge and water level indicator are mounted on the boiler at its left end. Steam safety valve and stop valve are mounted on the top of the drum. Blow –off cock is provided for the periodical removal of mud and sediments collected in the mud box.

Salient features:

- Its overall efficiency is higher than a fire tube boiler.

- The defective tubes can be replaced easily.

- All the components are accessible for inspection even during the operation.

- The draught loss is minimum compared with other boilers.

- Steam generation capacity and operating pressure are high compared with other boilers.

- The boiler rests over a steel structure independent of brick work so that the boiler may expand or contract freely.

- The water tubes are kept inclined at an angle of 100 –150 to promote water circulation.

Water tube boiler over fire tube boilers:

Advantages:

- Steam can be generated at very high pressures.

- Heating surface is more in comparison with the space occupied. In the case of water tube boilers.

- Steam can be raised more quickly than is possible with a fire tube boiler of large water capacity. Hence, it can be more easily used for variations of load.

- The hot gases flow almost at right angles to the direction of water flow. Hence maximum amount of heat is transferred to water.

- A good and rapid circulation of water can be made.

- Bursting of one or two tubes does not affect the boiler very much with regard to its working. Hence water tube boilers are sometimes called ‚safety boilers‛.

- The different parts of a water tube boiler can be separated. Hence it is easier to transport.

- It is suitable for use in steam power plants (because of the various advantages listed above).

Disadvantages:

- It is less suitable for impure and sedimentary water, as a small deposit of scale may cause the overheating and bursting of tubes. Hence, water treatment is very essential for water tube boilers.

- Maintenance cost is high.

- Failure in feed water supply even for a short period is liable to make the boiler overheated. Hence the water level must be watched very carefully during operation of a water tube boiler.